Industrial Electrical Work for New and Existing Systems

Arc Electric Inc handles new construction and planned maintenance for industrial electrical systems in Butte, Montana.

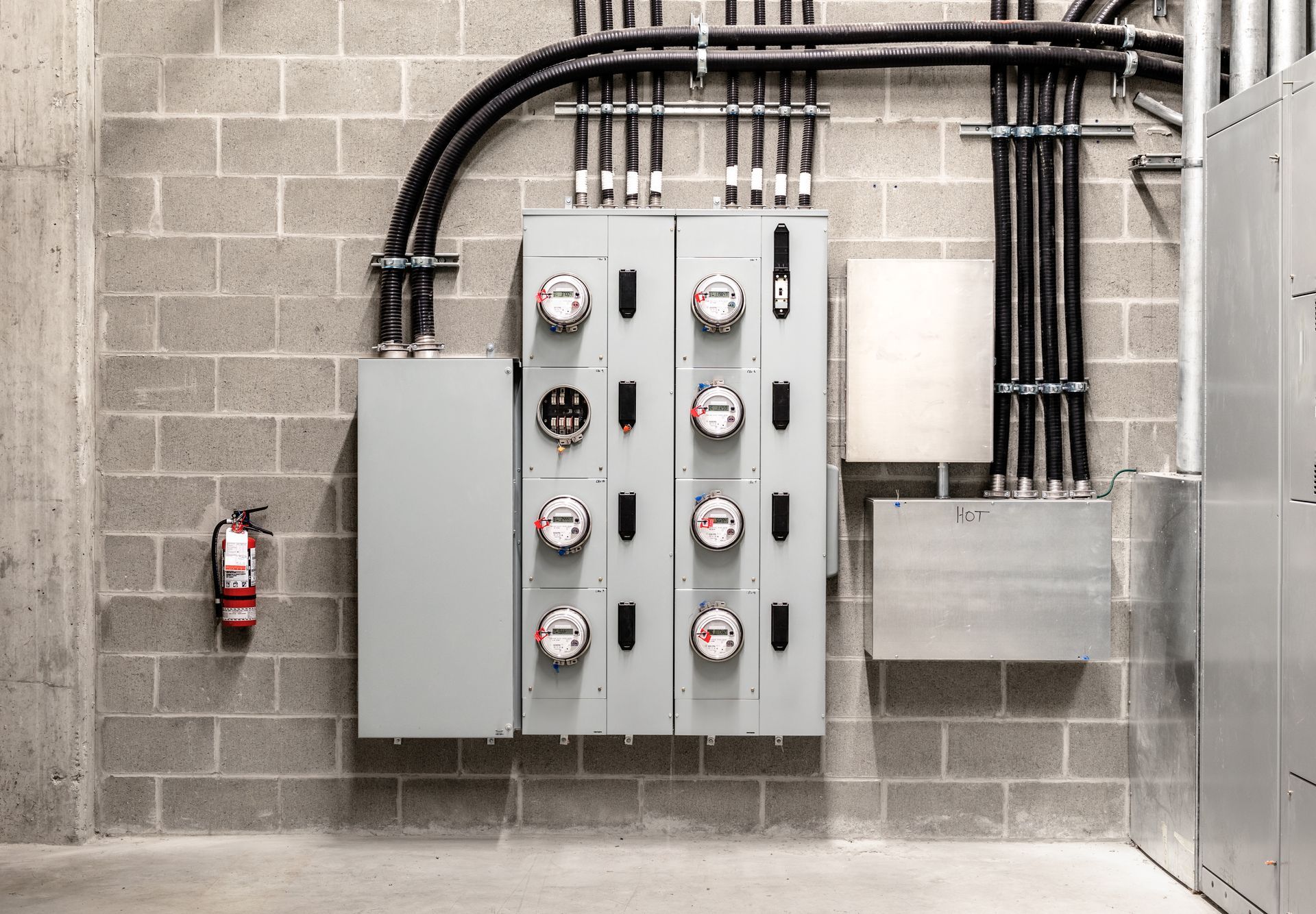

You are managing an industrial facility where electrical reliability directly affects production schedules, equipment uptime, and your ability to meet operational goals. Whether you are building a new facility in Butte or maintaining an existing one, your electrical systems must deliver consistent power to machinery, controls, and lighting without unplanned interruptions. Your electrical infrastructure includes distribution panels, motor circuits, control wiring, and grounding systems that must function correctly under continuous use.

Arc Electric Inc provides electrical work for new industrial construction projects and planned maintenance for operating facilities in Butte and the surrounding area. Your project may involve installing complete electrical systems in a new building, adding circuits to support production equipment, or performing scheduled inspections and repairs on existing panels and feeders. The work includes coordinating with facility managers and project teams to ensure electrical installations align with construction timelines and operational requirements.

Learn more about how Arc Electric Inc can support your industrial electrical system needs in Butte.

How Your System Performs After Installation or Maintenance

Your electrical work begins with reviewing your facility's load requirements, existing service capacity, and any planned equipment additions. In Butte, industrial facilities often require feeders sized for three-phase motors, distribution panels with space for future expansion, and conduit routing that avoids interference with mechanical systems or material handling paths. The installation includes wire sized for continuous duty, breakers selected for the connected load, and grounding that meets code requirements for industrial environments.

After your electrical system is installed or serviced, you will notice equipment that starts and runs without voltage fluctuations, control circuits that respond predictably, and a distribution system that supports your current operations with capacity for future growth. Your maintenance team will have access to labeled panels, clear circuit documentation, and electrical infrastructure that has been tested under load to confirm proper operation.

The work includes torquing terminal connections to manufacturer specifications, verifying circuit protection coordination, and confirming that emergency disconnect switches are accessible and clearly marked. Arc Electric Inc schedules installations and maintenance to minimize disruption to your operations and provides documentation of all completed work. The scope includes electrical systems within your facility and does not extend to utility-side equipment or substations unless specifically arranged.

We Know You Have Questions Before Starting

Industrial electrical projects involve decisions about system capacity, maintenance intervals, and coordination with other trades, and addressing these questions early helps set realistic expectations for both new construction and ongoing service.

Arc Electric Inc has completed electrical installations and maintenance throughout the Butte area for facilities that depend on reliable electrical systems to maintain production schedules. Contact Arc Electric Inc to discuss industrial electrical system needs specific to your operation.