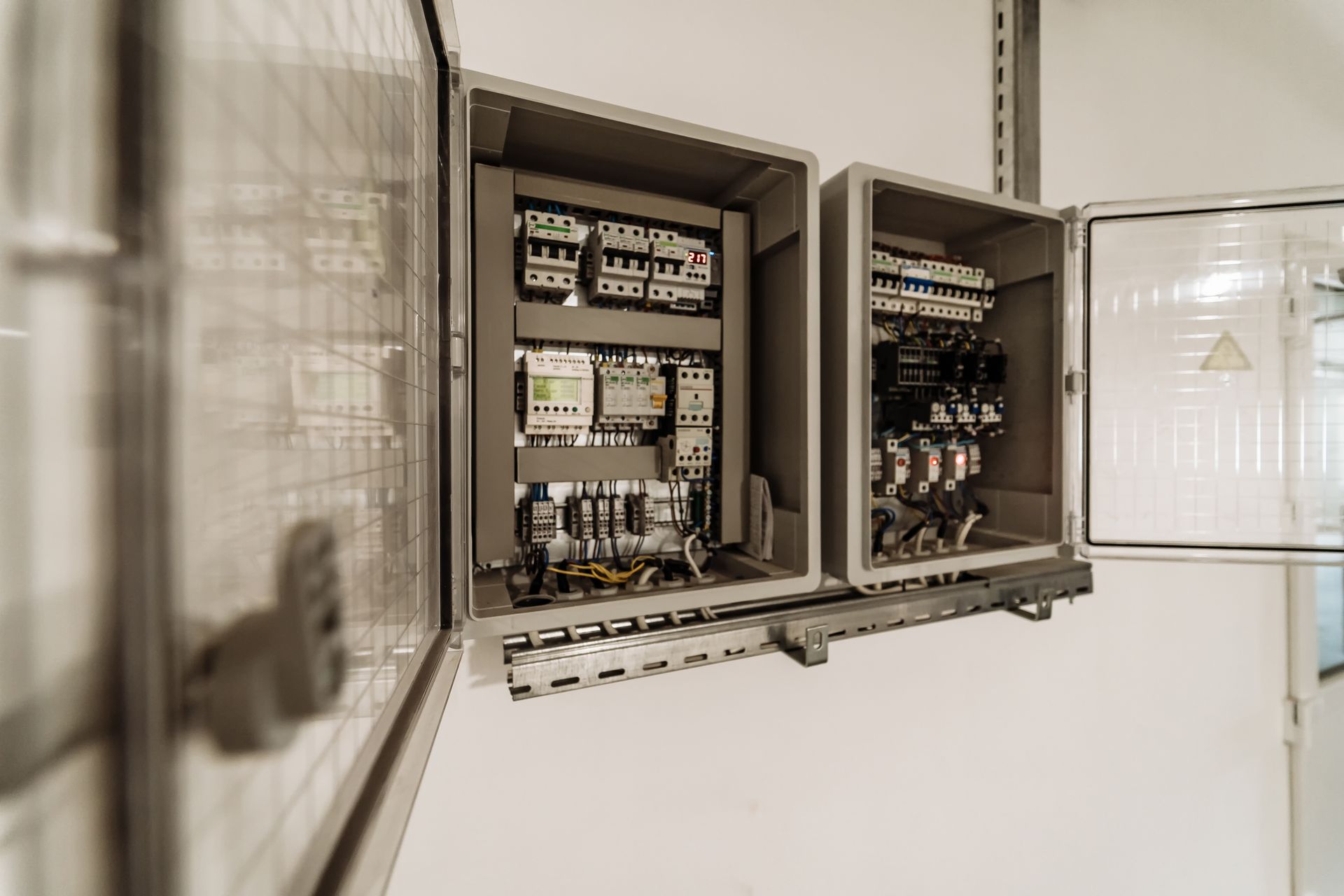

Heavy Electrical Systems Built for Industrial Use

Arc Electric Inc installs and maintains switchgear, transformers, and electrical distribution systems for industrial facilities in Butte, Montana.

When your facility loses power to a production line or a transformer starts running hot under load, the root cause often involves worn switchgear contacts, imbalanced phases, or distribution equipment that was never upgraded to match increased power demands. Industrial sites in Butte and the surrounding region face additional strain from extreme temperature swings, dust, and the vibration common in mining and heavy manufacturing environments.

Arc Electric Inc installs and services switchgear, large transformers, UPS systems, and complex electrical distribution networks for industrial facilities including mining operations, warehouses, and heavy equipment sites. The work includes new construction installations, ongoing maintenance contracts, and emergency repairs that address failures in critical power infrastructure. Every installation follows industrial safety standards and accounts for the operational requirements of facilities that run equipment around the clock.

Contact Arc Electric Inc for industrial electrical system support in Butte to install new equipment, troubleshoot distribution issues, or schedule preventive maintenance for transformers and switchgear.

How Industrial Electrical Work is Performed

Your electrician will review single-line diagrams, test voltage and current on each phase, and inspect connections for signs of arcing, corrosion, or overheating before performing any repairs or upgrades. In Butte industrial facilities where equipment has been running for decades, this often means coordinating planned outages, isolating circuits with lockout-tagout procedures, and replacing components while minimizing downtime.

After the service is complete, your switchgear will operate without hesitation, your transformers will run at stable temperatures under full load, and your UPS systems will provide clean backup power during utility interruptions or voltage sags. If new distribution equipment was installed, your facility will be able to add production lines or heavy machinery without overloading existing circuits or requiring temporary generators.

The electrician will also provide updated documentation showing panel schedules, transformer ratings, and breaker settings so maintenance staff can troubleshoot issues and plan future expansions. If your facility requires arc flash analysis, relay coordination, or thermal imaging to identify hot spots before failures occur, those services can be scheduled as part of a comprehensive maintenance program tailored to your site and equipment.

What Facility Managers Need to Know

Facility managers often want to know how long installations take, what documentation is provided after service, and how preventive maintenance schedules reduce the risk of unplanned outages.

Arc Electric Inc supports industrial facilities throughout Butte and the surrounding region, including mining operations and sites with heavy electrical infrastructure that require ongoing maintenance and rapid response when equipment fails. If your facility needs new switchgear installed, transformers serviced, or a preventive maintenance plan that keeps production running, learn more about how we can support your operation by reaching out to schedule a site assessment and review your current electrical distribution system.